How to deal with the blocked hammer mill

Hammer mill refers to the crusher that can grind, pulverize and crush a wide range of materials. It has been used in various industries for many years and often play an important role in the production of biomass pellet plant or feed pellet plant. To achieve the maximum performance of the hammer mill, it must operate with the correct speed, sufficient screen area for the applied horsepower, the proper hammer pattern and hammers should in the correct position.

The size of the finished product of the hammer mill varies according to different screen size, shaft speed or hammer configuration. For example, to get the finer finished product, the hammer mill should operate with faster speed, smaller screen and more hammers. Each component of the hammer mill can be changed individually or in any combination in order to produce the precise grind required.

The hammer mills are often blocked during the practical use which makes a lot of troubles to clients. The blocked hammer mill maybe has the disadvantages in design. But it is mainly caused by the wrong operation most of the time.

A. High feeding speed increase the workload of machine and blackened the machine. The blockage make the motor work with overload, if the time is long, the motor can be burned. As for this condition, lowering the feeding speed or close the feeding mouth instantly which can improve the feeding method. A feeder could be equipped for controlling the feeding amount. There are two types of feeders, which are manual operation control or automation control. The electricity currency is usually controlled at 85% of rated current during the operation of the crushing machine due to the high ration speed of hammer mill with high workload and high fluctuation rates.

B. The discharging tube is not smooth or blocked which make the wind mouth of crushing machine blocked; The machine is not matched with the transmitted tube which make the wind is weak in the tube or blocked without wind. After the failures are found, the wind mouth should be cleared at first. The improper transmitted equipment should be replaced and feeding amount should be adjusted, that make the equipment normal.

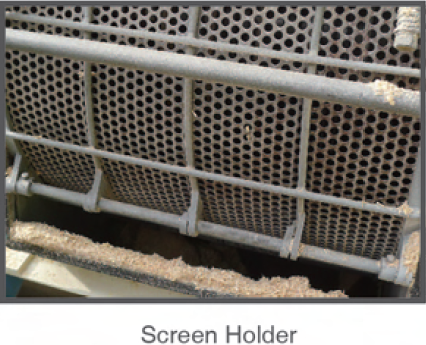

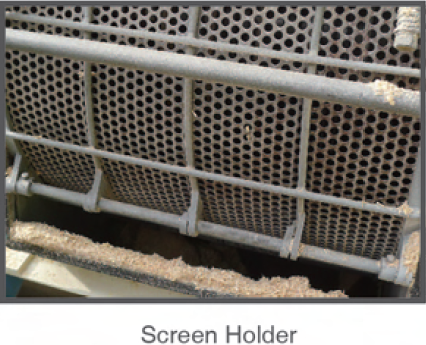

C. The hammer blade is broken or aged, the holes of screen are sealed or broken, high moisture content may causes the blockage of crushing machine. The broken or aged hammer blades should be replaced regularly and the screen should be checked up regulars. The moisture content should be lower than 14% which can improve the production efficiency without blocking of hammer mill.

A hammer mill of high quality can increase the productivity and improve the working efficiency of biomass pellet plant. KMEC provides all kinds of hammer mill with the features of elegant design, energy saving and less space occupation to meet different demands for pulverization. We are pleased to recommend the right hammer mill to you according to your raw materials and requirements for the finished products. Please feel free to contact us.

A hammer mill of high quality can increase the productivity and improve the working efficiency of biomass pellet plant. KMEC provides all kinds of hammer mill with the features of elegant design, energy saving and less space occupation to meet different demands for pulverization. We are pleased to recommend the right hammer mill to you according to your raw materials and requirements for the finished products. Please feel free to contact us.

-----------------------------------------------------------------------------------------------------------------------------------------------

News

- Small Pellet Machine Manufacturer-Kingman

- Application of Wood Pellets and Use of Biomass Pellets

- From Fossil Fuel into Biomass Pellet Fuel

- Biomass Pellet Making Machines Market

- Applying of pellet stoves for home use

- Highland pellets to build $130 million facility in arkansas

- How to deal with the blocked hammer mill

- How to Make Wood Pellets with Sawdust

- The government policy promotes the development of biomass fuel

- Market analysis of biomass pellet fuel

- Strategic positioning of renewable energy

- Biomass energy has pass through the pre assessment

- The key point of deep processing of biomass pellet

- Harbin is promoting the development of biomass machinery

- The development of biomass formation technology I

- The development of biomass formation technology II

- Biomass energy industry is now going full tilt in 2015

- Rapid increasing demand of sawdust pellet on the market

- Pellet fuel market in EU

- Chinese Biomass Energy Conference held in Beijing

- Future market development of straw pellet mill

- Peanut Shell Pellet Mill Makes High Quality Pellets

- The utilization of straw is only 5%, biomass energy needs our attention!

- Corn straw pellet machine relieves the tight supply of fuel energy

- Reasons for loose or not forming of biomass pellet mill