Basic Knowhow of Pellet Mill and Pellet Plant

The Pelletizing Process

Pelletization, since the beginning of the pellet mill and pellet plant industry, has been considered an art, or called a process involving imprecise measurement, uncertain results, and that indefinable quality of feel. This so-called “art” of pelletization came into being in an environment lacking the understanding of the effects occurring when the differing characteristics of feedstock are subjected to the pelletizing processes of heat, moisture, and pressure. No excuse, however, exists today for the uninformed pellet mill operator.

The science of feedstock processing has now reached a point that, by knowing the characteristics of raw material (moisture, content, fiber, etc.) and using machinery with accurate measurements, the guesswork has been removed from pelletizing. As a result, much more is required of the pellet mill operator in the way of knowledge and ability. The skill of the pellet mill operator, through his ability or mistakes, influences plant profitability. Pellet mill operators have a vitally important role in the manufacture of biomass pellets. They should recognize this responsibility and the great contribution they make to an efficient biomass pellet plant.

Link to How to start a pellet plant

INTRODUCTION TO PELLETIZING

The Purpose of Pelletizing of pellet mill and pellet plant

Pelletized biomass substances have been defined as “agglomerated pellets formed by extruding individual ingredients or mixtures by compacting and forcing through die openings by any mechanical process”. Basically, the purpose of pelletizing is to take a finely divided, sometimes dusty and difficult-to-handle biomass material and, by using heat, moisture and pressure, form it into larger particles. These larger particles are easier to handle and usually result in improved pelletized results when compared to the unpelletized loosened biomass materials. Pellets are generally formed with varied diameters due to different usage and will be somewhat longer than the diameter.

It is acknowledged that biomass pellets can be combusted with a higher thermal value than incompact biomass matters such as sawdust, saw shavings, rice husk and wheat straw. The most logical reasons are that (a) the heat generated in conditioning and pelletizing makes the materials more cohesive resulting in a huge increase in longer time of combustion, (b) the pellet simply puts the feed in a concentrated form, and (c) pelletizing minimizes waste during the material transportation and application. Feedstock conversion will be improved. These advantages are particularly noticeable in combustion of pellets both in domestic heating and industrial power-heat generation.

Pelletizing prevents the segregation of material in a mixing, handling or pelletizing process. Through surveys of pelletizing efficiency from pellet mill and pellet plant clients, it is proved that clients are more apt to receive a thoroughly mixed ration than one that has uneven and less uniform feedstock through these processes. It also has the pelletizing of pellet mill optimized. Bulk density is increased, which enhances storage capabilities of most bulk facilities. Shipping facilities are also increased, thereby reducing transportation costs. This is particularly evident in such fibrous ingredients as sawdust, rice husk, oat hulls, etc.. A better flow and handling characteristic of pellets is one of the least mentioned advantages but probably the most important, particularly as it relates to fuel consumers.

The process of producing biomass pellets can roughly be described as a plastic molding operation of the extrusion type through a pellet mill. Since different raw materials contain distinguished levels of lignin. When sufficiently controlled compression is applied to the “conditioned” feedstock, they will form a dense mass, shaped to conform to the die against which they are pressed. When the heat and moisture is again withdrawn (dried and cooled) as to withstand moderately rough handling without excessive breakage and has retained or enhanced its cohesive value.

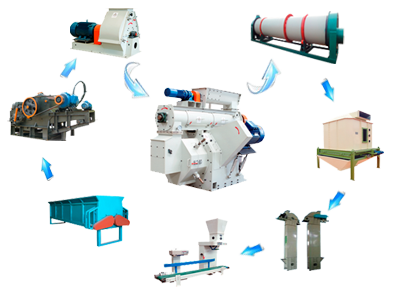

In modern pellet plants, the ingredients are usually stored in bins above a weighing system composed of one or more scales. Those ingredients, which are of coarse texture, are ground into a fine meal to facilitate the pelletizing and mixing process. In particular in a pellet plant adopting more than one kind of material, weighted quantities of each ingredient (either as a batch or continuously) are thoroughly mixed (either in a batch mixer of a continuous flow mixing unit) and then conveyed to a bin above the pellet mill. Some manufacturers have installed systems to grind all of their premixed materials prior to entering the pellet mill. Data is not available which indicates this has been an advantage or disadvantage on a consistent basis as far as durability is concerned.

Terms Used in Operation of Pellet Plant and Pellet Mill

The following terms are often used to measure the efficiency and quality of pellet mill operation.

Friction is the difference in temperature of the feedstock entering the pellet mill die and the pellet being discharged from the die. The difference reflects the mechanical energy required to produce pellets. There are several inherent factors that can affect friction:

1. Moisture addition to the feedstock. The amount of moisture (water) content should cease when the friction plateaus.Moisture added beyond this point will cause the pellets to disintegrate and not increase production or quality.

2. Conditioning. Conditioning is one of the most important factors in achieving good physical quality of pellets. Conditioning creates thermal, chemical and mechanical energy; the stream used during conditioning disrupts the structure of the starch and causes gelatinization and also plasticizes proteins and softens fibres. The process of gelatinization creates natural ‘glue’ which allows the particles to compress tightly and adhere to each other when passing through the pellet die.

3. Ground screen size of feedstock. Bulk density of ground feedstock depends on the particle size and particle size distribution. Particle size distribution also reflects on the available surface area. Particle sizes affect the true density of the feedstock and also influence durability. In general, all the feedstocks had more than 50% of the particle size in the range of 0.297–1.68mm as evident from the figure. Though different screen/sieves were used during grinding, similar trend of particle size distribution (normal distribution) was reported for switchgrass, olive tree pruning, barley, canola, oat, and wheat straws.

4. Physical properties of the feedstock ingredients, for example, fibrous content. Other factors relating to friction are pellet mill die size in terms of die pore diameter and thickness (also called pore depth). High friction (over 30°F) results in reduced die and roller life, as well as increased bearing and gear maintenance.

Fines are the materials that result from pellets disintegrating due to poor quality or mechanical attrition. Fines are a function of moisture and high friction or oversized feedstock particles or poor conditioning within pellet mill.

Shrinkage is the loss of weight of the original feedstock after pelletizing. This loss is basically due to lack of moisture addition and high friction. High levels of friction due to lack of moisture addition will lead to higher pellet temperature entering the cooler; and thus, more moisture is “flashed off”. Since you comprehend the basic knowledge of pellet mill and you can understand the working principle of pellet plant better.

--------------------------------------------------------------------------------------------------------------------------------------------------

News

- Small Pellet Machine Manufacturer-Kingman

- Application of Wood Pellets and Use of Biomass Pellets

- From Fossil Fuel into Biomass Pellet Fuel

- Biomass Pellet Making Machines Market

- Applying of pellet stoves for home use

- Highland pellets to build $130 million facility in arkansas

- How to deal with the blocked hammer mill

- How to Make Wood Pellets with Sawdust

- The government policy promotes the development of biomass fuel

- Market analysis of biomass pellet fuel

- Strategic positioning of renewable energy

- Biomass energy has pass through the pre assessment

- The key point of deep processing of biomass pellet

- Harbin is promoting the development of biomass machinery

- The development of biomass formation technology I

- The development of biomass formation technology II

- Biomass energy industry is now going full tilt in 2015

- Rapid increasing demand of sawdust pellet on the market

- Pellet fuel market in EU

- Chinese Biomass Energy Conference held in Beijing

- Future market development of straw pellet mill

- Peanut Shell Pellet Mill Makes High Quality Pellets

- The utilization of straw is only 5%, biomass energy needs our attention!

- Corn straw pellet machine relieves the tight supply of fuel energy

- Reasons for loose or not forming of biomass pellet mill