Sawdust Pellet Production Process Details

Sawdust, as the core raw material for biomass fuel pellet manufacturing, comes from a wide range of sources, mainly generated from sawing, grinding, milling and planing in sawmills. Globally, especially in the United States, Vietnam, Sweden, Finland, Norway and China, sawdust pellets are produced on a large scale and are widely used for heating, power generation, and all kinds of commercial and domestic fields, which are favored by the market. In recent years, the demand for sawdust pellets has grown exponentially in light of escalating energy costs, environmental concerns, and the increasing depletion of traditional energy sources.

According to an industry research report by PMarketResearch, as of 2022, global sales of wood pellets are projected to have approached 30 billion tons, creating an economic value of approximately $4.55 billion. In addition, the continuous rise in the cost of traditional fuels has further fueled the booming wood pellet production industry. In Europe, for instance, the price range for wood pellets in 2023 is between €300 and €400 per ton, which reflects the strong growth dynamics of the sustainable biomass energy market.

Sawdust Pellet Production Process

If you are planning to build a sawdust pellet plant to participate in sawdust pellet production, it's important to have an in-depth understanding of the production process. Below you will find a comprehensive overview of each key step in how sawdust is transformed into high-quality pellets.

Sawdust Pretreatment

The first step in sawdust pellet production is the pretreatment of the raw material. Sawdust collected from woodworking operations often contains impurities such as rocks and metal shavings. At the same time, the moisture content of the sawdust varies greatly, so the sawdust needs to be rigorously tested and moisture adjusted before pelletizing.

Ideally, the moisture content of sawdust for pellet production should be between 10% and 15%. If the moisture content exceeds this range, the sawdust needs to be dried to ensure that the pelletizing process is carried out smoothly.

Sawdust drying

In view of the moisture content of sawdust has a decisive impact on the quality of particles, so the drying process is particularly important. For the pellets sold on the market, its moisture content is best maintained between 8% and 10%. Excessive moisture will result in lower pellet quality, lower energy density and impaired pellet mill efficiency.

During the drying process, sawdust is usually dewatered in a rotary drum dryer or airflow dryer to achieve the required moisture standard. However, care should be taken to avoid over-drying, so as not to affect the lignin content, which is the key component that binds the sawdust particles together in the pelletizing process.

Sawdust screening and crushing (optional)

Before further processing, the sawdust is screened to remove foreign objects that could damage the machine, such as stones, metals and plastics. Screening is usually done with the help of stone traps and magnetic separators to ensure that non-organic debris is completely removed.

In addition, if the sawdust contains large pieces of wood, a shredding step becomes essential. By pulverizing, the particle size of the raw material can be reduced to ensure the uniformity of the final particles and smooth passage through the die holes of the pellet mill.

Sawdust pelletizing

Granulation is the core of sawdust pellet production. In this process, sawdust is fed into the pellet mill, compressed and molded into particles under high pressure. The granulation process mainly includes the following steps:

Heat generation: As the sawdust passes through the pellet mill, heat is generated due to the friction between the material and the mold. This causes the temperature of the sawdust to rise rapidly to approximately 120-130°C (248-266°F). At this temperature, the lignin in the sawdust softens and acts as a natural binder, helping the pellets to bond tightly.

Compression and molding: The heated sawdust is forced through the die holes of the pellet mill to form cylindrical pellets. A cutting mechanism then trims the pellets to the desired length standard.

Additive use (if necessary): If the lignin content of the sawdust is low or the natural bonding effect is not good, additives or binders can be used in appropriate amounts to improve the molding effect and durability of the pellets.

Cooling of sawdust pellets

Newly produced pellets are hot and soft, so they need to be cooled before storage or packaging. The cooling process is critical to the hardening of the pellets and the reduction of moisture content.

During the cooling process, the pellets are usually cooled down using an air cooling system or a counter-current cooler. After cooling, the moisture content of the pellets should be controlled at around 6%. Subsequently, the pellets will absorb some moisture from the air and eventually stabilize in the range of 8% to 10% moisture content.

Sawdust particles screening and packaging

Before packaging and transportation, the particles need to be screened again to remove fine particles and dust that may affect the quality. The fines produced during the screening process can be recycled or used as an additional fuel source.

The packaging process is customized to the destination and use of the pellets. For household or small-scale shipments, pellets are usually packaged in 12 kg, 15 kg or 20 kg bags. For large-scale shipments, pellets are usually packed in bulk bags (1 ton per bag) or transported in bulk and protected from moisture using plastic packaging. Proper packaging ensures that the pellets maintain their quality consistency and are easy to store and transport without reducing their efficiency.

Frequently asked questions about building sawdust pellet plants

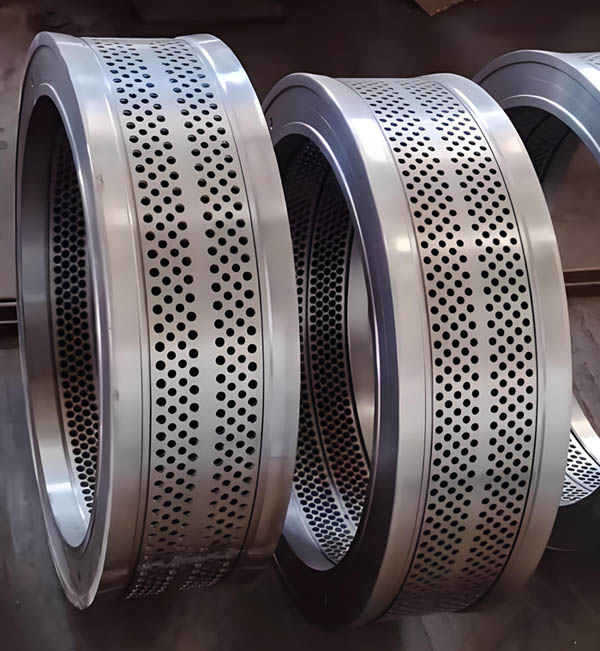

1. What kind of raw material is used for ring die molds?

Ring die molds used in pellet mills can be made of either alloy steel or stainless steel. Although alloy steel is cheaper, stainless steel is more durable and resistant to wear. High-quality pelletizers (such as KMEC's pelletizers) often use stainless steel for longer service life.

2. What is the typical size of the end product wood pellet?

The diameter of the sawdust pellets can be adjusted depending on the ring die mold used. Common pellet diameters range from 6 to 10 millimeters and the length can be adjusted with a pellet cutter.

3. What is the ideal moisture content of the raw material?

The optimal moisture content of sawdust is between 15% and 18%. This moisture level ensures the highest quality of the pellets and the best possible bonding properties during the production process.

4. Do you offer a pellet mill installation service?

Yes, we offer installation services and can send an engineer to set up and optimize your wood pellet mill according to your requirements and location.

Whether you are looking to start a small scale operation or expand to a larger commercial scale line, understanding the entire process is key to ensuring success.

News

- Small Pellet Machine Manufacturer-Kingman

- Application of Wood Pellets and Use of Biomass Pellets

- From Fossil Fuel into Biomass Pellet Fuel

- Biomass Pellet Making Machines Market

- Applying of pellet stoves for home use

- Highland pellets to build $130 million facility in arkansas

- How to deal with the blocked hammer mill

- How to Make Wood Pellets with Sawdust

- The government policy promotes the development of biomass fuel

- Market analysis of biomass pellet fuel

- Strategic positioning of renewable energy

- Biomass energy has pass through the pre assessment

- The key point of deep processing of biomass pellet

- Harbin is promoting the development of biomass machinery

- The development of biomass formation technology I

- The development of biomass formation technology II

- Biomass energy industry is now going full tilt in 2015

- Rapid increasing demand of sawdust pellet on the market

- Pellet fuel market in EU

- Chinese Biomass Energy Conference held in Beijing

- Future market development of straw pellet mill

- Peanut Shell Pellet Mill Makes High Quality Pellets

- The utilization of straw is only 5%, biomass energy needs our attention!

- Corn straw pellet machine relieves the tight supply of fuel energy

- Reasons for loose or not forming of biomass pellet mill