The Best Homemade Wood Pellet Press Manufacturer

What is homemade wood pellet press? Some people may raise the question. Homemande wood pellet press is also called Flat Die Pellet Mill which is usually used domestically rather than on an industrial scale. Homemade wood pellet press, as its name suggests, can be used individually in your courtyard or garage to produce wood pellets fuel at home. Pellet mill is a kind of forming machine to compress tightly biomass material such as wood sawdust and rice husk into pellets as green fuel which is a better replacement of conventional fossil fuel.

Raw material for the homemade biomass pellet mill should be strictly controlled in size and moisture content. The wood pellet mill can process a variety of wood species such as polar, pinewood, beech, cedar and agro waste such as rice husk, wheat straw, cotton stalks or cotton stalks to create biomass pellets. According to statistics and experience of us, moisture content of material shall be kept around 13%-15%, with the size of material less than 5mm. If the material you use caters to the demands above, you can put it into direct use with a flat die pellet mill.

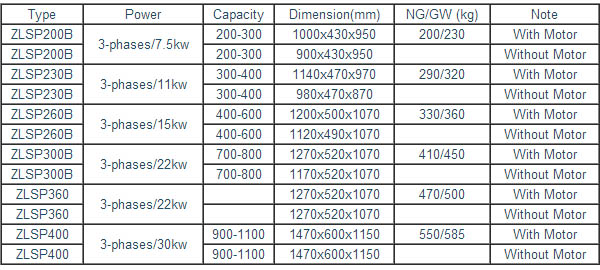

If you want to pretreat disqualified material, we can also offer corresponding auxiliary equipment such as wood crusher and drying system. But it will seem like a small-sized industrial production, Actually all the equipment can be used separately or in a combined way. If your raw material is oversized and also with a higher moisture content, besides, you also possess a large place to store machines, we can also offer you small pellet plant, or called moveable pellet plant to produce a comparactively low production yield of pellets fuel such as 200kg/h or 300kg/h. Normally, a requirement for 500kg/h or above can be met with the offer of a ring die pellet plant which actually is for industrial use at most time. Besides the above, you should also take into consideration power supply you can provide. Otherwise, it cannot bring machines to work.

We also would like to tell you about size of pellets. The most commonly used pellet sizes are 6mm and 8mm, but the homemade biomass pellets are usually 6mm in diameter. Actually the 6mm ones do have the advantages compared to the 8mm, such as faster combustion and even higher compressed density. However, the difference between them is not quite distinctive. Therefore, you can tell that raw material should be cut into smaller pieces than 6mm so that it can be processed into pellets via pellet die pores which is 6mm or 8mm in diameter accordingly.

Since then the crushing capability of crusher or hammer mill is bound to be compatible with performance of homemade pellet press.

KMEC is a professional supplier of series of wood pellet mill. We have accumulated many years of experience of pellet making process. Our primary products include series flat die pellet press, ring die pellet mill production line etc. we welcome customers all over the world to consult and purchase our products. We look forward to build good business relationship with you in the future!

News

- Small Pellet Machine Manufacturer-Kingman

- Application of Wood Pellets and Use of Biomass Pellets

- From Fossil Fuel into Biomass Pellet Fuel

- Biomass Pellet Making Machines Market

- Applying of pellet stoves for home use

- Highland pellets to build $130 million facility in arkansas

- How to deal with the blocked hammer mill

- How to Make Wood Pellets with Sawdust

- The government policy promotes the development of biomass fuel

- Market analysis of biomass pellet fuel

- Strategic positioning of renewable energy

- Biomass energy has pass through the pre assessment

- The key point of deep processing of biomass pellet

- Harbin is promoting the development of biomass machinery

- The development of biomass formation technology I

- The development of biomass formation technology II

- Biomass energy industry is now going full tilt in 2015

- Rapid increasing demand of sawdust pellet on the market

- Pellet fuel market in EU

- Chinese Biomass Energy Conference held in Beijing

- Future market development of straw pellet mill

- Peanut Shell Pellet Mill Makes High Quality Pellets

- The utilization of straw is only 5%, biomass energy needs our attention!

- Corn straw pellet machine relieves the tight supply of fuel energy

- Reasons for loose or not forming of biomass pellet mill